Liquid Polycarboxylate Superplasticizer SPF-300

- KELONG CHEMICAL

- CHINA

- 1 WEEK

- 100000 TONS/YEAR

1. High water reduction: The water reduction rate of liquid Polycarboxylate Superplasticizer SPF-300 is above 25%.

2. Good slump retention ability: Delaying time of transporting concrete and time of detention at construction site, guarantee concrete pumpability.

3. High strength gained rate: Greatly increasing early and after strength, reducing energy loss. Reduction of cracking, shrinkage and creep.

4. Wide adaptability: Polycarboxylate Superplasticizer SPF-300 is compatible with ordinary silicate cement, silicate cement, slag silicate cement and all kinds of blendings having excellent dispersibility and plasticity.

Liquid Polycarboxylate Superplasticizer SPF-300

Product Introduction

Polycarboxylate Superplasticizer SPF-300 is a new environmental polycarboxylate superplasticizer. It is a concentrated product. Best high water reduction, high slump retention ability, low alkali content for the product. And Liquid Polycarboxylate Superplasticizer SPF-300 having high strength gained rate. It can be widely used in premix of common concrete, gushing concrete, high strength and durability concrete. Especially! It can be used in high strength and durability concrete having excellent capability.

Principle of Function

Molecular main chain of polycarboxylate high performance water reducer is firmly adsorbed on surface of cement granule where can efficiently counteract hydration reaction and increase its plasticity. Branched chain surround cement granule having sterically hindered and electrostatic exclusion function which is different from conventional imparts excellent dispersing ability and effect of water reducing which make integrative characteristics of concrete improve greatly.

Characteristics

1. High water reduction: The water reduction rate of Polycarboxylate Superplasticizer SPF-300 is above 25%.

2. Easying to control production: Controling water reduction ratio, plasticity and air entraining by adjusting molecular weight of main chain, length and density of side chain, type of side chain group.

3. Good slump retention ability: Delaying time of transporting concrete and time of detention at construction site, guarantee concrete pumpability.

4. Good adhesion: Making concrete have excellent workability, Non-layer, without segregation and bleeding.

5. Good dispersion: High fluidity of concrete results in deposing and compacting easily for self-compacting concrete.

6. High strength gained rate: Greatly increasing early and after strength, reducing energy loss. Reduction of cracking, shrinkage and creep.

7. Wide adaptability: Polycarboxylate Superplasticizer SPF-300 is compatible with ordinary silicate cement, silicate cement, slag silicate cement and all kinds of blendings having excellent dispersibility and plasticity.

8. Good strength and durability: low lacuna rate, low alkali and chlorin-ion content. Enhancing concrete strength and durability

9. Environmental friendly products: No pollution during production.

Methods of Use

1. The dosage of Liquid Polycarboxylate Superplasticizer SPF-300 is suggested as follows(wt.% of cement):0.25%-0.8%.

2. Liquid Polycarboxylate Superplasticizer SPF-300 can be mixed in metric water or added in concrete admixture. The recommended stirring time is 150s at least. Concrete mixing test should be made before using in order to insure concrete quality.

3. Liquid Polycarboxylate Superplasticizer SPF-300 can be compounded together retarder, defoamer, air-entertaining reagent, lignin sulfonic natrium and so on.

4. Liquid Polycarboxylate Superplasticizer SPF-300 is sold as raw materials. It is not suggested to use SPF-300 products directly in concrete or other materials without formulation blending. The compatibility of SPF-300 products to particular cement, aggregate and the other raw materials in the application is not guaranteed. It should be obtained through trial mixes and formulation technologies by the users.

Scope of Application

1. SPF-300 is a polycarboxylate superplasticizer used in premix of construction and cast-in-place concrete.

2. It is especially suitable high strength concrete for railway, haven, traffic, bridge and electric power and so on.

3. It is suitable for the preparation of high strength, high durability, self-compacting, steel fiber and self-leveling concrete.

Technical Specification

Items | Unit | Specification |

Density | g/cm3 | 1.10±0.02 |

PH | 6.0-8.0 | |

Solid Content | % | 40.5±1.0 |

Cl- | % | ≤0. 1 |

Na2SO4 | % | ≤1.0 |

Physical & Mechanical Properties

Test Items | Specification | Test Result | |

Water Reduction Rate% | ≥25 | 39.5 | |

Bleeding Ratio% | ≤60 | 0 | |

Air Content% | ≤6.0 | 4.2 | |

Slump Retention 60min(mm) | ≤80 | 41 | |

Compressive Strength Ratio% | ≥160 | 220 | |

3d | ≥160 | 206 | |

7d | ≥150 | 187 | |

28d | ≥140 | 152 | |

Package & Storage

1. Packing: IBC tank.

2. Stored at 0-35℃, far away from sunlight.

3. Shelflife is normally six month. It is tested eligibility and then used when it exceeds.

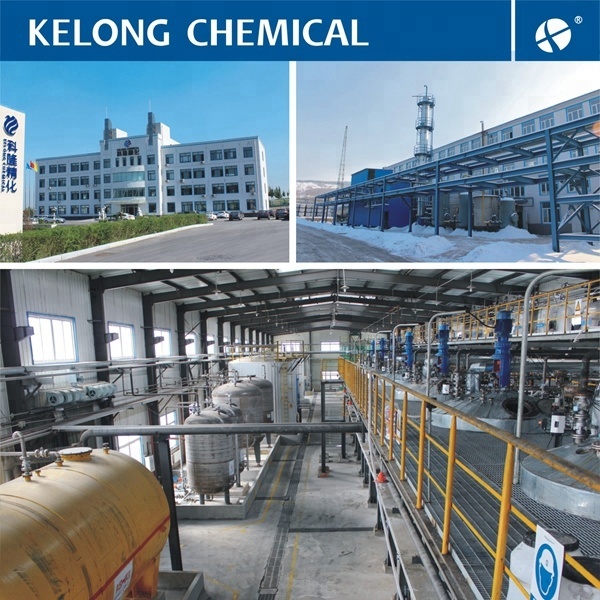

Liaoning Kelong Fine Chemical Co., Ltd is founded in 1988, headquartered in Liaoning National High-tech Industrial Base for Aromatic Hydrocarbons and Fine Chemicals,covering an area of 200,000 square meters.

Mainly engaged in R&D, manufacturing, sales and service of fine chemical green energy-saving new material series products with ethylene oxide as the main raw material, and has satisfied perfect product lines for polycarboxylate superplasticizer, cement grinding aid, cosmetics preservative, nonionic surfactants, etc.